In pharmaceutical manufacturing, success does not begin with equipment — it begins with layout.

A well-planned facility flows like a controlled ecosystem. Materials move logically. People move safely. Air flows intentionally. Compliance is built into the walls.

Pharma facility layout and master planning is not architectural drafting. It is a strategic discipline that combines GMP regulations, production efficiency, contamination control, expansion strategy, and operational psychology.

If you are planning a greenfield pharmaceutical plant or expanding an existing site, this guide explores how intelligent master planning becomes your long-term competitive advantage.

- Why Pharma Layout Planning Is a Critical Investment

A poorly designed pharmaceutical facility leads to:

- Cross-contamination risks

- Regulatory observations

- Inefficient material movement

- Production bottlenecks

- Expansion limitations

- High operational cost

A properly designed pharma layout ensures:

Logical process flow

GMP compliance by design

Controlled contamination risk

Efficient manpower utilization

Utility optimization

Seamless scalability

Layout mistakes are expensive to correct after construction. Master planning prevents those mistakes.

- What Is Pharma Master Planning?

Master planning is the strategic blueprint of the entire pharmaceutical campus. It defines:

- Land utilization

- Building positioning

- Production zoning

- Utility corridors

- Traffic movement

- Future expansion areas

- Environmental compliance zones

It answers one fundamental question:

How will this facility operate efficiently for the next 20 years?

- Core Principles of Pharmaceutical Facility Layout Design

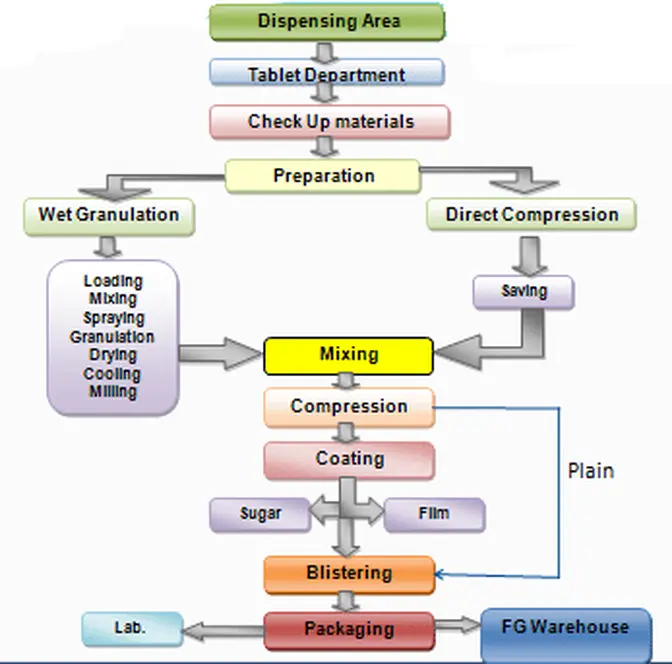

- 1️⃣ Unidirectional Material Flow

Raw materials should move forward — never backward.

Typical flow:

Raw Material Warehouse → Dispensing → Manufacturing → Packing → Finished Goods → Dispatch

Backtracking increases contamination and mix-up risk.

- Segregation Strategy

Pharmaceutical layouts must segregate:

- Raw vs finished goods

- Sterile vs non-sterile zones

- High potency vs general production

- Personnel vs material movement

- Waste exit vs product flow

Segregation is a GMP requirement, not a design preference.

- Zoning Based on Risk Classification

Different product types require different zoning:

OSD (Oral Solid Dosage)

Dust containment & pressure cascade control

- Sterile Injectable

ISO-classified cleanrooms & controlled access

- API Manufacturing

Hazardous area classification & solvent handling zones

- Biotech & Vaccine

Biosafety level segregation

Master planning integrates all risk zones into a unified campus structure.

- HVAC and Pressure Cascade Planning

Airflow defines compliance.

Layout must support:

- Proper air handling unit (AHU) placement

- Pressure differential zoning

- Return air strategy

- Clean corridor concept

- Service corridors

HVAC routing must be integrated at planning stage — not retrofitted later.

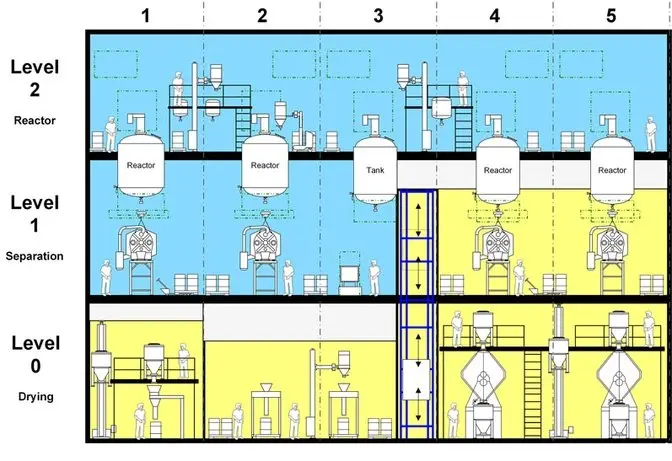

- Utility & Service Corridor Integration

Modern pharma facilities include:

- Dedicated technical corridors

- Interstitial service floors

- Maintenance access without production interruption

- Centralized utility backbone

Smart master planning reduces maintenance downtime.

- Greenfield vs Brownfield Pharma Layout Planning

- Greenfield Facility

- Full design flexibility

- Optimal zoning possibilities

- Easier regulatory alignment

- Higher capital investment

- Brownfield Expansion

- Space constraints

- Utility capacity limitations

- Validation challenges

- Operational continuity risks

A structured feasibility study helps determine expansion viability.

- Warehouse & Logistics Integration

Pharma layout must incorporate:

- Quarantine areas

- Sampling rooms

- Temperature-controlled storage

- Hazardous storage rooms

- Automated racking systems

- Separate dispatch zones

Logistics inefficiency silently reduces plant productivity.

Common Pharma Layout Mistakes to Avoid

Cross-over between personnel and material

Insufficient expansion planning

Poor waste exit planning

Oversized corridors without functional purpose

Ignoring maintenance accessibility

Improper cleanroom airlock positioning

Small design oversights create long-term compliance challenges.

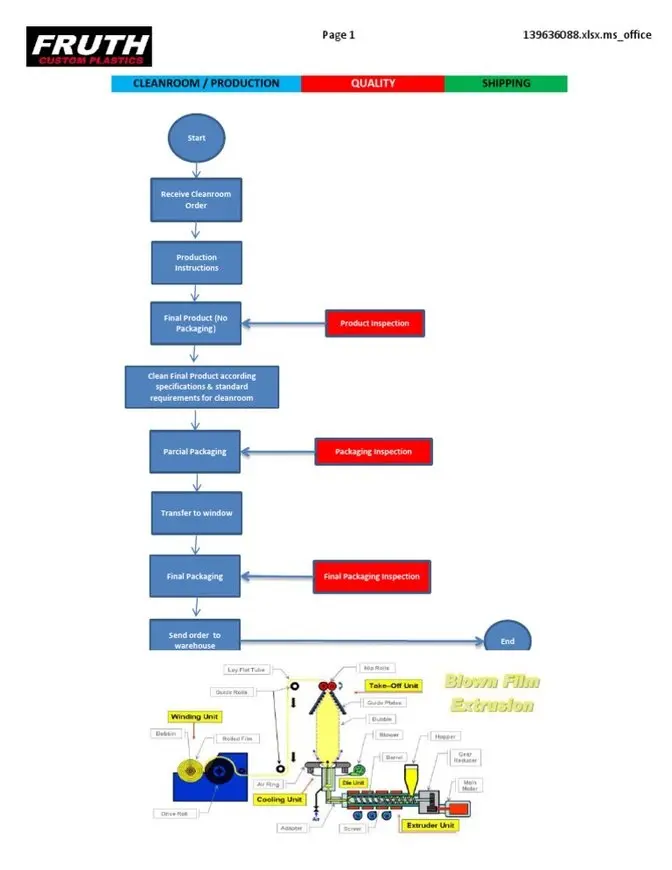

- Future-Ready Pharma Master Planning Trends (2026 & Beyond)

Pharma infrastructure is evolving toward:

- Modular production suites

- Flexible multi-product facilities

- Digital twin layout simulation

- Energy-efficient campus planning

- ESG-compliant site design

- Automation-integrated flow modeling

Future-ready layouts support process upgrades without structural modification.

How Professional Pharma Layout Consultants Add Value

xperienced pharma layout consultants provide:

GMP-aligned architectural design

Risk-based zoning strategy

Regulatory inspection readiness

Process-driven layout optimization

Utility capacity forecasting

Long-term scalability planning

Their expertise reduces redesign costs and regulatory delays.

The Strategic Impact of Master Planning

A well-designed pharmaceutical facility:

- Reduces production cycle time

- Improves contamination control

- Enhances audit confidence

- Minimizes energy consumption

- Increases operational efficiency

- Strengthens long-term asset value

Master planning is not a cost — it is an investment in compliance and profitability.

Final Thoughts

Pharma facility layout and master planning determine how efficiently your plant will operate for decades.

Walls, corridors, cleanrooms, warehouses, and utilities must align with process flow and regulatory expectations from day one.

Whether you are planning:

- An OSD manufacturing plant

- A sterile injectable facility

- An API production unit

- A biotech or vaccine site

- Or a multi-product pharmaceutical campus

Strategic master planning ensures your facility is compliant, scalable, and future-ready.